Abstract

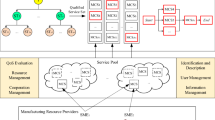

Cloud manufacturing (CMfg) is a new service-oriented manufacturing paradigm that enables distributed collaboration between manufacturers. As logistics between geographically dispersed manufacturers is indispensable in CMfg environment, and the responsibility for the whole lifecycle of products becomes more important for manufacturers, we have taken into account both forward and reverse logistics services in CMfg. Unlike most of the research in the field, this paper not only addresses the special needs of CMfg system from reverse logistics perspective but also considers the transportation of returned products. For this purpose, an agent-based architecture for tackling reverse flows in CMfg is suggested which includes eight agents: buy-back price determiner, reverse flow cost determiner, resell price determiner, return rate forecaster, redistribution of returned products, transportation planner, supplying planner and manufacturing process planner. To demonstrate the applicability of the proposed agent-based architecture, the performance of transportation planner agent is optimized via genetic algorithm. In addition, its performance is compared to a non-intelligent scenario of assigning and sequencing transportation resources in a distributed manufacturing environment. The results show that Transportation Planner agent reduces the transportation costs of CMfg service providers and the time that their vehicles are traveling while being unloaded.

Similar content being viewed by others

References

Keller M, Rosenberg M, Brettel M, Friederichsen N (2014) How virtualization, decentrazliation and network building change the manufacturing landscape: an industry 4.0 perspective. Int J Mech Aerosp Ind Mechatron Manuf Eng 8(1):37–44. https://doi.org/10.1016/j.procir.2015.02.213

Botta A, De Donato W, Persico V, Pescape A (2014) On the integration of cloud computing and internet of things. Int Conf Future Internet Things Cloud FiCloud 56:23–30. https://doi.org/10.1109/FiCloud.2014.14

Mell PM, Grance T (2011) The NIST definition of cloud computing. Gaithersburg. https://doi.org/10.6028/NIST.SP.800-145

Adamson G, Wang L, Holm M, Moore P (2015) Cloud manufacturing—a critical review of recent development and future trends. Int J Comput Integr Manuf 3052(March):1–34. https://doi.org/10.1080/0951192X.2015.1031704

Xu X (2012) From cloud computing to cloud manufacturing. Robot Comput Integr Manuf 28(1):75–86. https://doi.org/10.1016/j.rcim.2011.07.002

Wu D, Greer MJ, Rosen DW, Schaefer D (2013) Cloud manufacturing: strategic vision and state-of-the-art. J Manuf Syst 32(4):564–579. https://doi.org/10.1016/j.jmsy.2013.04.008

Akbaripour H, Houshmand M, van Woensel T, Mutlu N (2018) Cloud manufacturing service selection optimization and scheduling with transportation considerations: mixed-integer programming models. Int J Adv Manuf Technol 95(1–4):43–70. https://doi.org/10.1007/s00170-017-1167-3

Tseng ML, Islam MS, Karia N, Fauzi FA, Afrin S (2019) A literature review on green supply chain management: trends and future challenges. Resour Conserv Recycl. https://doi.org/10.1016/j.resconrec.2018.10.009

Agrawal S, Singh RK (2019) Analyzing disposition decisions for sustainable reverse logistics: triple bottom line approach. Resour Conserv Recycl. https://doi.org/10.1016/j.resconrec.2019.104448

Kawa A, Golinska P (2010) Supply chain arrangements in recovery network. In: Jędrzejowicz P, Nguyen NT, Howlet RJ, Jain LC (eds) Agent and multi-agent systems: technologies and applications. KES-AMSTA 2010. Lecture notes in computer science, vol 6071. Springer, Berlin. https://doi.org/10.1007/978-3-642-13541-5_30

Julianelli V, Caiado RGG, Scavarda LF, Cruz SP (2020) Interplay between reverse logistics and circular economy: Critical success factors-based taxonomy and framework. Resour Conserv Recycl. https://doi.org/10.1016/j.resconrec.2020.104784

He W, Xu L (2015) A state-of-the-art survey of cloud manufacturing. Int J Comput Integr Manuf 28(3):239–250. https://doi.org/10.1080/0951192X.2013.874595

Tao F, Zhang L, Venkatesh VC, Luo Y, Cheng Y (2011) Cloud manufacturing: a computing and service-oriented manufacturing model. Proc Inst Mech Eng Part B J Eng Manuf 225(10):1969–1976. https://doi.org/10.1177/0954405411405575

Esmaeilian B, Behdad S, Wang B (2016) The evolution and future of manufacturing: a review. J Manuf Syst 39:79–100. https://doi.org/10.1016/j.jmsy.2016.03.001

Ning F, Zhou W, Zhang F, Yin Q, Ni X (2011) The architecture of cloud manufacturing and its key technologies research. In: CCIS2011—Proc 2011 IEEE int conf cloud comput intell syst, pp 259–263. https://doi.org/10.1109/CCIS.2011.6045071

Ren L, Zhang L, Zhao C, Chai X (2013) Cloud manufacturing platform: operating paradigm, functional requirements, and architecture design. In: Volume 2: systems; micro and nano technologies; sustainable manufacturing. ASME V002T02A009. https://doi.org/10.1115/MSEC2013-1185

Valilai OF, Houshmand M (2013) A collaborative and integrated platform to support distributed manufacturing system using a service-oriented approach based on cloud computing paradigm. Robot Comput Integr Manuf 29(1):110–127. https://doi.org/10.1016/j.rcim.2012.07.009

Akbaripour H, Houshmand M, Fatahi Valilai O (2015) Cloud-based global supply chain: a conceptual model and multilayer architecture. ASME J Manuf Sci Eng 137(4):040913. https://doi.org/10.1115/1.4030887

Škulj G, Vrabič R, Butala P, Sluga A (2017) Decentralised network architecture for cloud manufacturing. Int J Comput Integr Manuf 30(4–5):395–408. https://doi.org/10.1080/0951192X.2015.1066861

Tao F, Zuo Y, Da XuL, Zhang L (2014) IoT-Based intelligent perception and access of manufacturing resource toward cloud manufacturing. IEEE Trans Ind Inform 10(2):1547–1557. https://doi.org/10.1109/TII.2014.2306397

Liu X, Li Y, Wang L (2015) A cloud manufacturing architecture for complex parts machining. J Manuf Sci Eng 137(6):61009. https://doi.org/10.1115/1.4029856

Li X, Song J, Huang B (2016) A scientific workflow management system architecture and its scheduling based on cloud service platform for manufacturing big data analytics. Int J Adv Manuf Technol 84(1–4):119–131. https://doi.org/10.1007/s00170-015-7804-9

Yang C, Lan S, Shen W, Huang GQ, Wang X, Lin T (2017) Towards product customization and personalization in IoT-enabled cloud manufacturing. Cluster Comput 20(2):1717–1730. https://doi.org/10.1007/s10586-017-0767-x

Laili Y, Lin S, Tang D (2020) Multi-phase integrated scheduling of hybrid tasks in cloud manufacturing environment. Robot Comput Integr Manuf. https://doi.org/10.1016/j.rcim.2019.101850

Kerdlap P, Low JSC, Ramakrishna S (2019) Zero waste manufacturing: A framework and review of technology, research, and implementation barriers for enabling a circular economy transition in Singapore. Resour Conserv Recycl. https://doi.org/10.1016/j.resconrec.2019.104438

Arnold U, Oberlander J, Schwarzbach B (2012) LOGICAL—development of cloud computing platforms and tools for logistics hubs and communities. In: Comput Sci Inf Syst (FedCSIS), 2012 Fed Conf, pp 1083–1090

Oberländer J, Franczyk B (2014) Cloud-based cooperation of logistics service providers in logistics cluster organisations. Fed Conf Comput Sci Inf Syst 3:237–244. https://doi.org/10.15439/2014F130

Subramanian N, Abdulrahman MD, Zhou X (2015) Integration of logistics and cloud computing service providers: cost and green benefits in the Chinese context. Transp Res Part E Logist Transp Rev 74:81–93. https://doi.org/10.1016/j.tre.2014.12.006

Niharika G, Ritu V (2015) Cloud architecture for the logistics business. Proc Comput Sci 50:414–420. https://doi.org/10.1016/j.procs.2015.04.013

Kong XTR, Fang J, Luo H, Huang GQ (2015) Cloud-enabled real-time platform for adaptive planning and control in auction logistics center. Comput Ind Eng 84:79–90. https://doi.org/10.1016/j.cie.2014.11.005

Fisher O, Watson N, Porcu L, Bacon D, Rigley M, Gomes RL (2018) Cloud manufacturing as a sustainable process manufacturing route. J Manuf Syst 47:53–68. https://doi.org/10.1016/j.jmsy.2018.03.005

Vincent Wang X, Lopez NBN, Ijomah W et al (2015) A smart cloud-based system for the weee recovery/recycling. J Manuf Sci Eng 137(6):61010. https://doi.org/10.1115/MSEC2014-4109

Wang XV, Wang L (2016) A cloud-based production system for information and service integration: an internet of things case study on waste electronics. Enterp Inf Syst 11(7):1–17. https://doi.org/10.1080/17517575.2016.1215539

Mashhadi AR, Behdad S, Zhuang J (2016) Agent based simulation optimization of waste electrical and electronics equipment recovery. J Manuf Sci Eng 138(10):101007. https://doi.org/10.1115/1.4034159

Khajavi LT, Seyed-Hosseini S-M, Makui A (2011) An integrated forward/reverse logistics network optimization model for multi-stage capacitated supply chain. iBusiness 3(2):229–235. https://doi.org/10.4236/ib.2011.32030

Ramezani M, Bashiri M, Tavakkoli-Moghaddam R (2013) A new multi-objective stochastic model for a forward/reverse logistic network design with responsiveness and quality level. Appl Math Model 37(1–2):328–344. https://doi.org/10.1016/j.apm.2012.02.032

Ayvaz B, Bolat B, Aydın N (2015) Stochastic reverse logistics network design for waste of electrical and electronic equipment. Resour Conserv Recycl 104:391–404. https://doi.org/10.1016/j.resconrec.2015.07.006

Dutta P, Das D, Schultmann F, Fröhling M (2016) Design and planning of a closed-loop supply chain with three way recovery and buy-back offer. J Clean Prod 135:604–619. https://doi.org/10.1016/j.jclepro.2016.06.108

Kumar VNSA, Kumar V, Brady M, Garza-Reyes JA, Simpson M (2017) Resolving forward-reverse logistics multi-period model using evolutionary algorithms. Int J Prod Econ 183:458–469. https://doi.org/10.1016/j.ijpe.2016.04.026

Polotski V, Kenné JP, Gharbi A (2018) Production control of hybrid manufacturing–remanufacturing systems under demand and return variations. Int J Prod Res 7543:1–24. https://doi.org/10.1080/00207543.2018.1461272

Goldberg DE, Holland JH (1988) Genetic algorithms and machine learning. Mach Learn 3(2):95–99. https://doi.org/10.1023/A:1022602019183

Whitley D (1994) A genetic algorithm tutorial. Stat Comput 4:65–85. https://doi.org/10.1017/CBO9781107415324.004

Moons S, Ramaekers K, Caris A, Arda Y (2017) Integrating production scheduling and vehicle routing decisions at the operational decision level: a review and discussion. Comput Ind Eng 104:224–245. https://doi.org/10.1016/j.cie.2016.12.010

Vidal T, Crainic TG, Gendreau M, Lahrichi N, Rei W (2012) A hybrid genetic algorithm for multidepot and periodic vehicle routing problems. Oper Res 60(3):611–624. https://doi.org/10.1287/opre.1120.1048

Ghassemi Tari F, Hashemi Z (2016) A priority based genetic algorithm for nonlinear transportation costs problems. Comput Ind Eng 96:86–95. https://doi.org/10.1016/j.cie.2016.03.010

Hiassat A, Diabat A, Rahwan I (2017) A genetic algorithm approach for location-inventory-routing problem with perishable products. J Manuf Syst 42:93–103. https://doi.org/10.1016/j.jmsy.2016.10.004

Fazayeli S, Eydi A, Kamalabadi IN (2018) Location-routing problem in multimodal transportation network with time windows and fuzzy demands: presenting a two-part genetic algorithm. Comput Ind Eng 119:233–246. https://doi.org/10.1016/j.cie.2018.03.041

Xiao Y, Konak A (2018) A genetic algorithm with exact dynamic programming for the green vehicle routing & scheduling problem. J Clean Prod 167:1450–1463. https://doi.org/10.1016/j.jclepro.2016.11.115

Guo L, Qiu J (2018) Optimization technology in cloud manufacturing. Int J Adv Manuf Technol 97(1–4):1181–1193. https://doi.org/10.1007/s00170-018-1991-0

Akbaripour H, Houshmand M (2020) Service composition and optimal selection in cloud manufacturing: landscape analysis and optimization by a hybrid imperialist competitive and local search algorithm. Neural Comput Appl 32:10873–10894. https://doi.org/10.1007/s00521-018-3721-9

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hamidi Moghaddam, S., Akbaripour, H. & Houshmand, M. Integrated forward and reverse logistics in cloud manufacturing: an agent-based multi-layer architecture and optimization via genetic algorithm. Prod. Eng. Res. Devel. 15, 801–819 (2021). https://doi.org/10.1007/s11740-021-01069-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-021-01069-9